Highway FD Series Pressure Digger Models, Features, and Specifications

Model FD-30

Features

- 62,000 ft/lbs of torque

- 18,000 lb. controlled free fall winch with two speed

- 25,000 lbs. crowd force

- 30′ digging depth

- Square 2-bar design with solid inner kelly bar

- Truck or track-mounted carrier

- Standard Features

Model FD-30 LP

Features

- 62,000 ft/lbs of torque

- 18,000 lb. controlled free fall winch with two speed

- 25,000 lbs. crowd force

- 30′ digging depth

- Square 3-bar design

- Low profile mast

- Truck or track mounted carrier

- Standard Features

Model FD-40

Features

- 62,000 ft/lbs of torque

- 18,000 lb. controlled free fall winch with two speed

- 25,000 lbs. crowd force

- 40′ digging depth

- Square 2-bar design with solid inner kelly bar

- Truck or track-mounted carrier

- Standard Features

Model FD-50

Features

- 62,000 ft/lbs of torque

- 18,000 lb. controlled free fall winch with two speed

- 25,000 lbs. crowd force

- 50′ digging depth

- Square 2-bar design with solid inner kelly bar

- Truck or track-mounted carrier

- Standard Features

Model FD-60

Features

- 62,000 ft/lbs of torque

- 18,000 lb. controlled free fall winch with two speed

- 25,000 lbs. crowd force

- 60′ digging depth

- Square 2-bar design with solid inner kelly bar

- Truck or track-mounted carrier

- Standard Features

Standard FD Series Pressure Digger Features

Oversized Sheaves

Severe bending is a major cause of short wire rope life. By contrast, the larger the sheave diameter, the less wear on the rope and the greater its strength and life efficiency. Highway uses oversized sheaves to insure long life.

Adjustable Tie Down Blocks

The sliding hold-down blocks are built on a centric to allow for the tightening of the block as the slide pads wear. Ensures longer life out of wear pads and is easily adjusted by removing one bolt and turning to adjust.

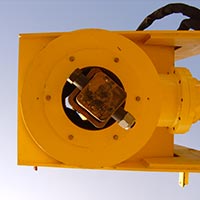

Kelly Bar Roller Drive

Highway’s standard kelly bar roller drive applies torque to the outer kelly bar and allows the bar to travel up and down freely and not create friction as with some drives.

Sealed Sheave Bearings

All sheave bearings are cone and race designs with protective rubber seals. The rubber seals keep out moisture and hold in grease to ensure longer operating life. The bearing and race can just be replaced so you don’t have to get a new sheave assembly if it is still in good working order.

Joystick Controls

Dual joystick controls at both armrests allow the operator to control all of the machine’s functions without having to remove his hands from the controls to find a different lever. These functions are fully proportional and allow precise control or feathering of movements.

Controlled Free Fall Winch

Standard controlled free fall winch allows the operator to dial in the fall rate determined by different tool weights and as not to create a “birds nest” of the cable. The pressure of the free fall can be seen on the operator’s control screen for easy tuning.

Digital Display

Highways digital display allows the operator to view all aspects of the machine’s functions. Oil temp, system hydraulic pressures, engine and transmission functions as well as drilling depths. There is also a fault code page that will tell you which function is not working to cut down on troubleshooting and repair time.

Adjustable Slewing Gear

Our adjustable slewing gear drive allows you to adjust the backlash by just removing a view bolts and turning the planetary clockwise or counterclockwise to set the proper backlash and gear mesh.

Solid Inner Kelly

Highway’s standard 4.25″ solid inner kelly bar gives long life to the bar and the end can be machined to fit your auger boxes. The extra weight of the kelly bar also adds to the crowd weight while drilling and in some soils the crowd function is not necessary.

CAN Bus Diagnostics

CAN Bus diagnostics allow the operator to monitor the entire machine, from proper valve function and system pressures to oil and fuel levels and faulty components. This saves time in diagnosing problems in the controls or hydraulic systems. In emergency situations, the system can be disabled, enabling it to run manually.

Protected Grease Zerks

Critical grease zerks are recessed into the pins to protect them against hooking on tag lines, preventing damage to the zerk or cable.

Boom Mounted Winches

Highway mounts their winches on the boom. This way, the operator doesn’t have to worry about paying in or out while positioning the mast assembly. Just raise the mast and go to work.

Zinc Plated Components

Highway Zinc plates all of its sheaves, pins, and accessories to ensure long duty cycles. The pins won’t rust up and will stay freely moving as long as grease is applied as specified.

Drop Case Gear Reduction

Highway’s step drop case is a heavy-duty design the keeps our drive lines in alignment and creates a deeper ratio to incur more torque. The dropbox can be adjusted on the lower input shaft through an eccentric for quick in-field adjustments. This extra reduction also protects the transmission from shock load.